Discover the power of tap handles to stand out from the crowd and ignite consumer interest

Case Studies

Tröegs Family Redesign

Blue Moon Belgian White

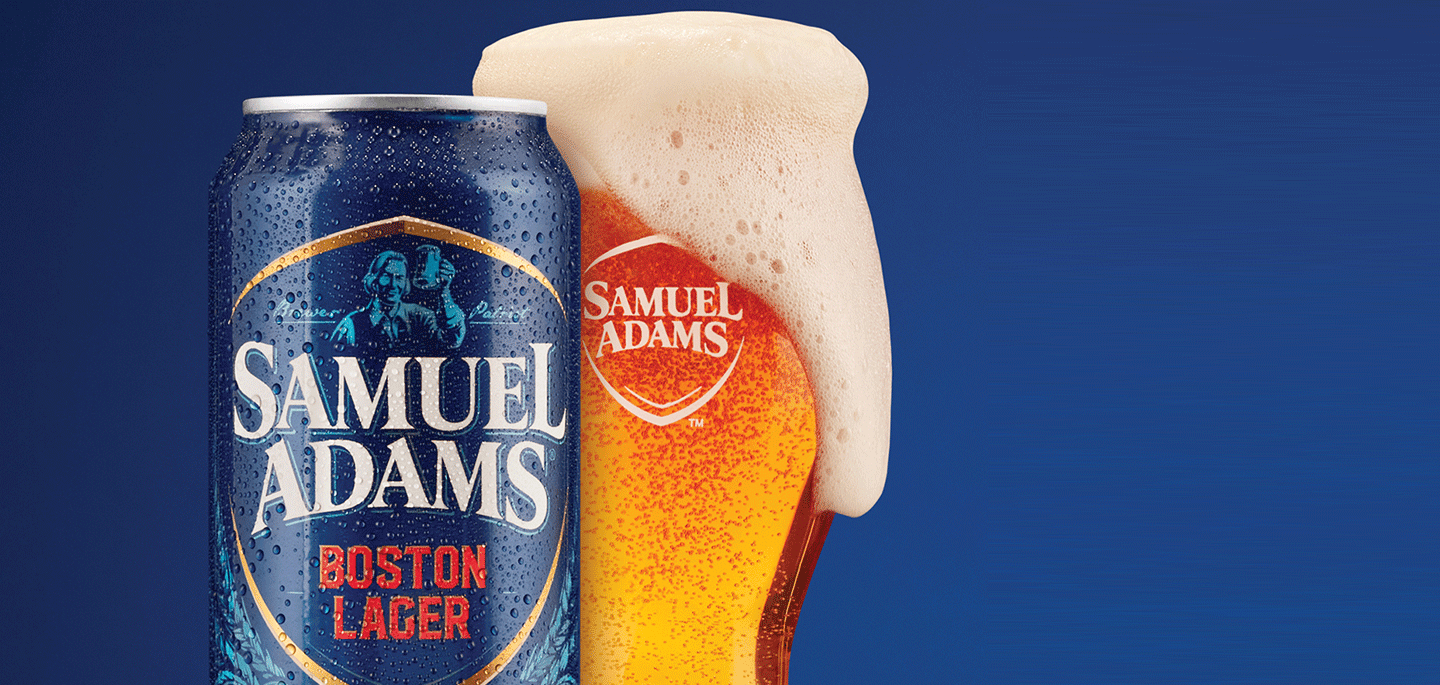

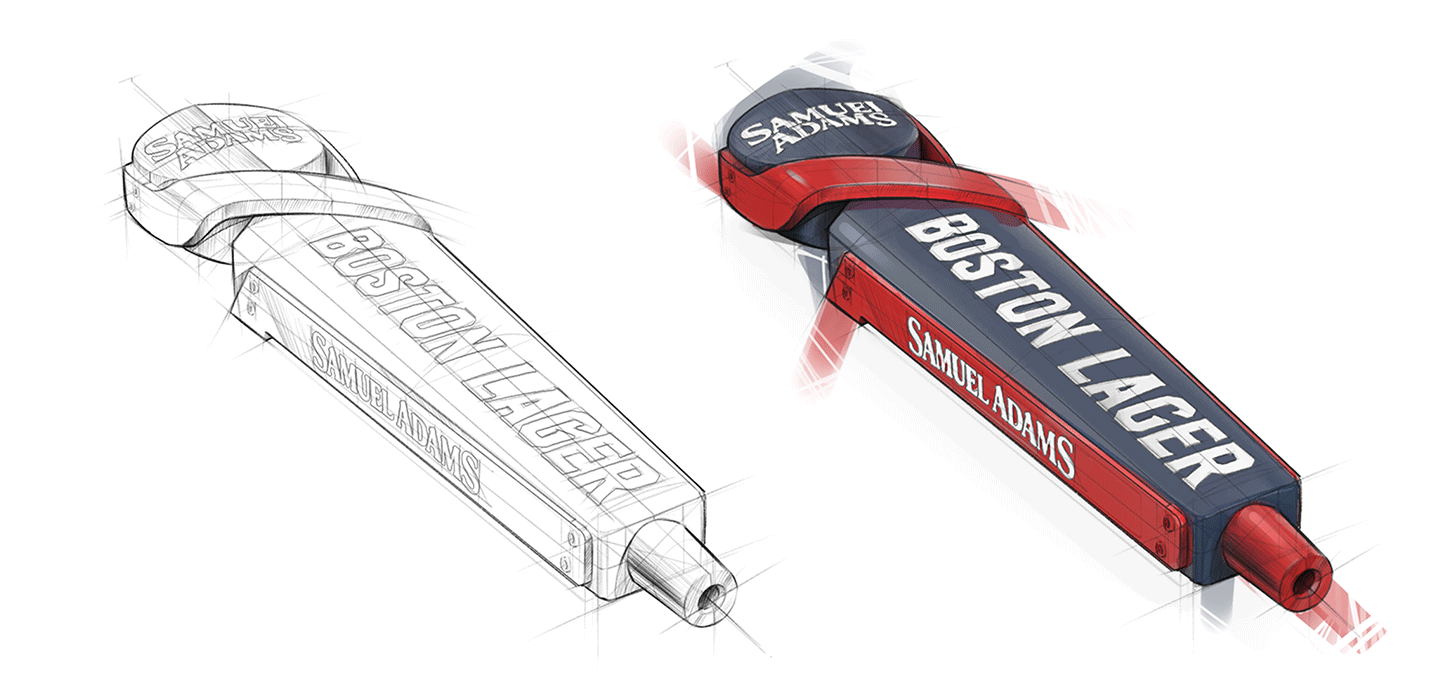

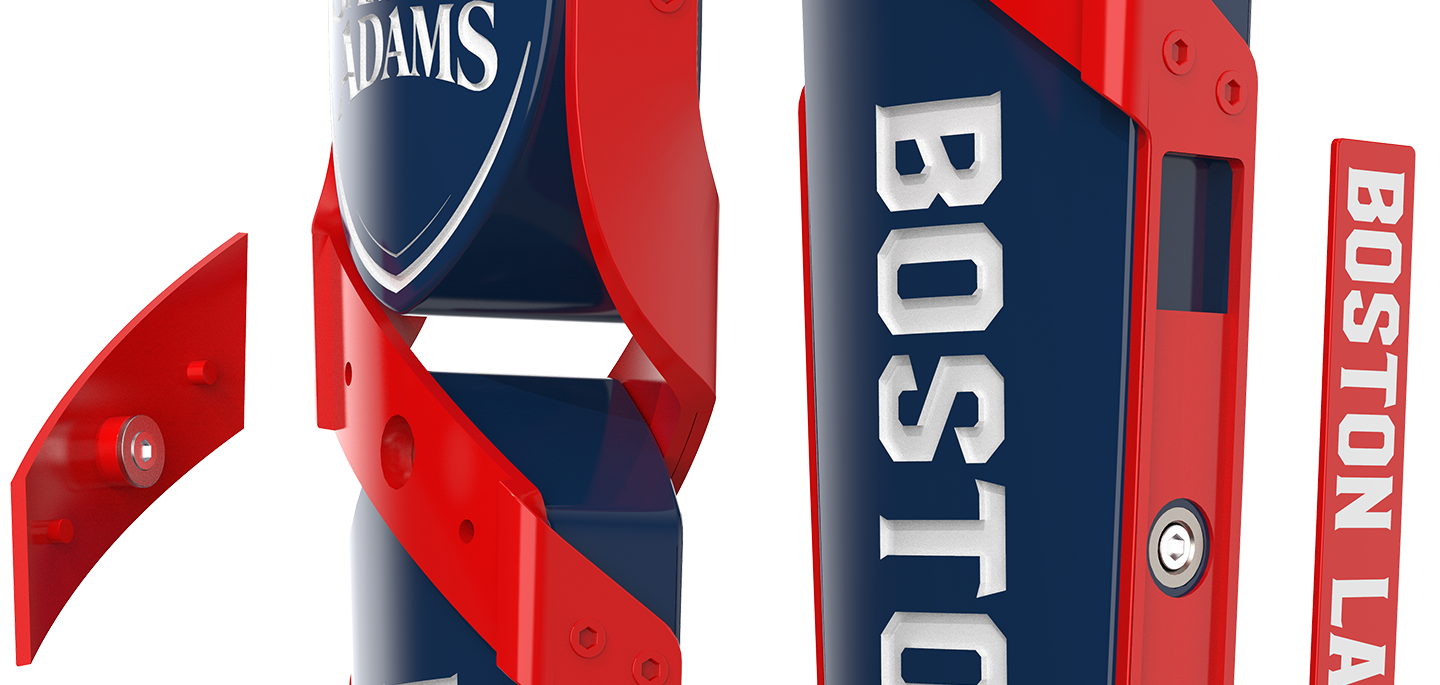

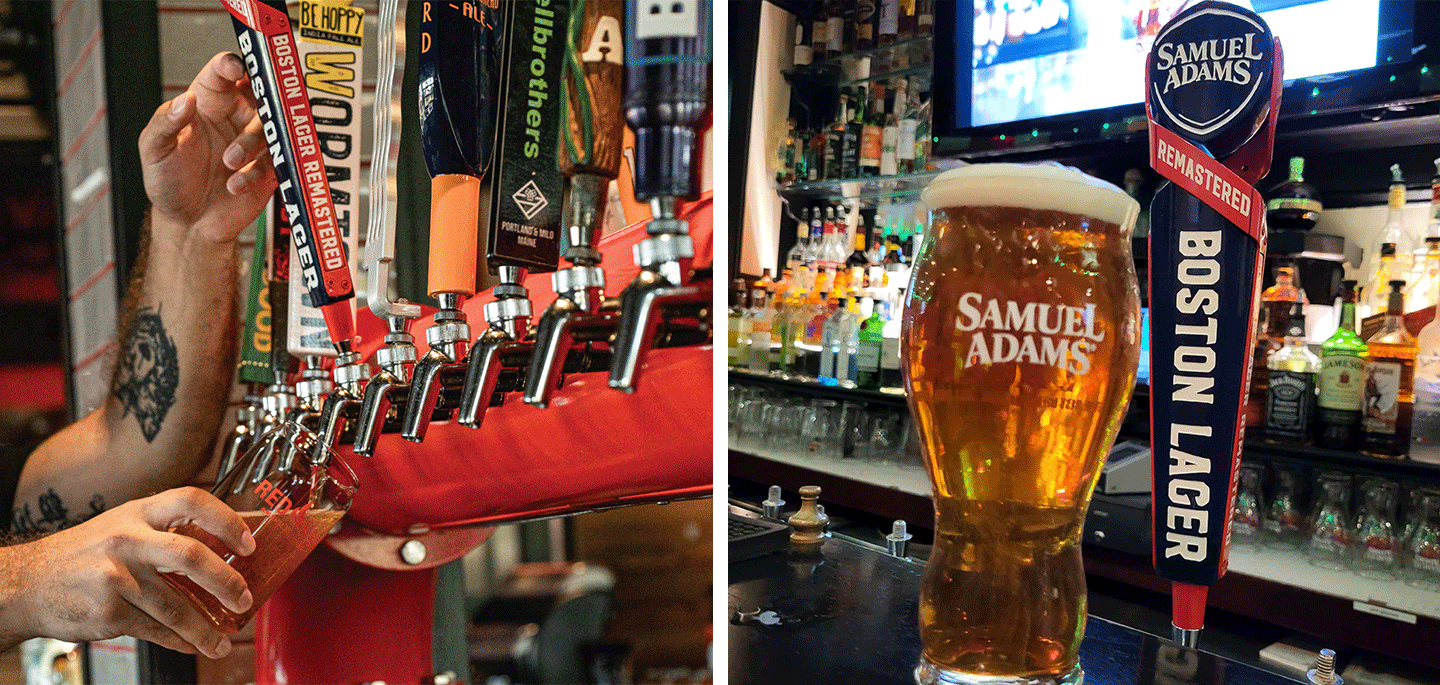

Samuel Adams Boston Lager

Case Study

Tröegs Family Redesign

Translating new visual identities to powerful on-premise marketing tools